B-pillar replacement is a critical automotive repair process ensuring vehicle safety and structural integrity by reconnecting key components precisely. Structural adhesive bonding is favored for its strength, versatility in material selection, design flexibility, efficiency, and cost-effectiveness compared to traditional methods like welding or riveting. Success depends on strategic planning, thorough preparation, using the right tools, materials (including automotive-grade adhesives), cleaning surfaces, addressing existing damage, and ensuring compatibility with modern cars' advanced features.

In modern automotive design, efficient and safe structural integrity is paramount. B-pillar replacement stands out as a critical aspect in achieving this, demanding precise adherence to material science and engineering principles. This article explores the dynamic interplay between B-pillar replacement and structural adhesive bonding. We delve into understanding specific requirements, uncovering significant advantages of this bonding technique, and providing strategic insights for successful implementation, ensuring enhanced vehicle safety and performance.

- Understanding B-Pillar Replacement Requirements

- Advantages of Structural Adhesive Bonding

- Implementation Strategies for Successful Results

Understanding B-Pillar Replacement Requirements

Understanding B-Pillar Replacement Requirements

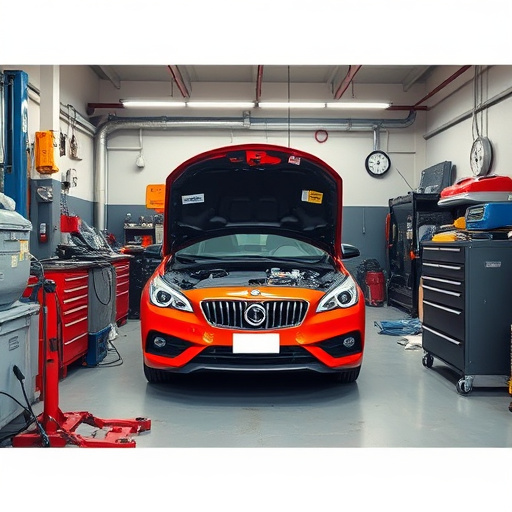

B-pillar replacement is a critical aspect of automotive repairs and maintenance, primarily focusing on structural integrity and safety. In an automotive body shop, this process involves the careful removal and replacement of the B-pillar, a key component that connects the roof, doors, and side panels, ensuring the vehicle’s stability in case of a collision. The challenge lies in matching the new pillar to the original specifications, especially with modern cars featuring advanced design aesthetics and safety standards.

This process requires meticulous planning and execution, considering factors like material compatibility, precision fitting, and adhering to manufacturer guidelines. For example, when repairing or replacing a bumper, the B-pillar must be accurately aligned to maintain the vehicle’s structural integrity. Body shop services that specialize in this area employ advanced techniques, including structural adhesive bonding, to ensure robust bonds that meet both performance and aesthetic criteria.

Advantages of Structural Adhesive Bonding

Structural Adhesive Bonding offers numerous advantages when it comes to B-pillar replacement, making it a preferred method in modern vehicle repair and restoration. One of its key benefits is the ability to create a strong, long-lasting bond between different materials, such as metal and glass. This is particularly valuable when replacing a B-pillar, which requires precise alignment and secure attachment to both the vehicle’s frame and window panel. Unlike traditional welding or riveting methods, adhesive bonding allows for greater flexibility in terms of material selection and design choices. It can accommodate complex geometries and intricate shapes, ensuring that the repaired area maintains its structural integrity without compromising aesthetics.

Additionally, this technique offers advantages in terms of repair efficiency and cost-effectiveness in a vehicle body shop. Adhesive bonding can often result in faster turnaround times compared to frame straightening or extensive metalwork. The process is less disruptive to surrounding components, reducing the need for excessive material removal or restructuring. This not only saves time but also minimizes the potential for damage to other parts of the vehicle during the B-pillar replacement process, making it a more precise and controlled repair method.

Implementation Strategies for Successful Results

Successful B-pillar replacement and structural adhesive bonding require a strategic approach. One key strategy is meticulous planning and preparation, ensuring all necessary tools, materials, and safety equipment are readily available. This includes selecting the right adhesives designed for automotive applications, as compatibility with various car parts is crucial for long-lasting bonds.

Additionally, proper surface preparation is vital before applying adhesive. This involves cleaning, degreasing, and sanding the surfaces to ensure optimal bonding. At this stage, addressing any existing damage, like minor car scratch repair or auto glass replacement, can prevent future issues and strengthen the overall structure. Many auto collision centers prioritize these steps to guarantee that when the B-pillar is replaced, it fuses seamlessly with the existing vehicle framework.

B-pillar replacement using structural adhesive bonding offers a revolutionary approach to automotive design and repair, ensuring enhanced safety, improved durability, and reduced weight. By understanding the specific requirements of B-pillar replacement and leveraging the advantages of this advanced bonding technique, manufacturers can achieve exceptional results. Implementing successful strategies, including material selection, surface preparation, and precise application, is key to unlocking the full potential of structural adhesive bonding for lasting and robust connections in modern vehicles.