Successful B-pillar replacement in autos requires adhering to industry standards for safety and structural integrity. Using advanced inspection tools like magnifying glasses and digital calipers ensures precise measurements and approved materials for strength and flexibility. Proper techniques, including LED light inspection, prevent misalignment and poor paint quality. Double-checking measurements and installation, plus thorough surface prep and suitable paints, ensure seamless, high-quality B-pillar replacements.

In today’s automotive industry, ensuring the quality control of B-pillar replacements is paramount for vehicle safety and structural integrity. This comprehensive guide delves into essential practices for managing this critical process. From understanding stringent B-pillar replacement standards to mastering inspection tools and techniques, we equip professionals with strategies to identify and mitigate common issues. By adhering to these tips, workshops can maintain superior craftsmanship, ensuring every replaced B-pillar meets the highest safety benchmarks.

- Understanding B-Pillar Replacement Standards

- Essential Inspection Tools and Techniques

- Common Issues & How to Avoid Them

Understanding B-Pillar Replacement Standards

Understanding B-Pillar Replacement Standards is paramount in the automotive industry, especially for ensuring vehicle safety and structural integrity during auto maintenance or car body restoration processes. The B-pillar, a critical component connecting the roof to the car’s sides, plays a vital role in crash protection. Therefore, replacement standards are designed to guarantee that any new B-pillars installed adhere strictly to manufacturer specifications.

These standards cover various aspects, from precise measurements and material composition to the quality of welds and finish. For instance, auto glass repair professionals must replace B-pillars with identical or approved materials, ensuring they meet structural requirements for both strength and flexibility. This meticulous attention to detail is crucial not just for the car’s aesthetics but more so for passenger safety during everyday driving, underscoring the importance of adhering to established B-pillar replacement practices in auto maintenance routines.

Essential Inspection Tools and Techniques

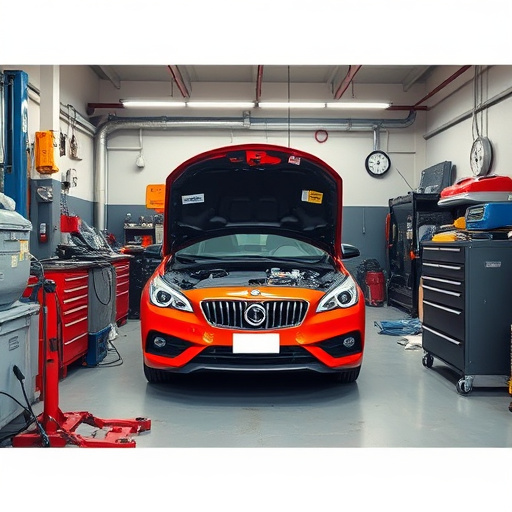

When conducting B-pillar replacement, having the right inspection tools and techniques is paramount to ensure quality control. A comprehensive set includes a variety of items tailored for precision and accuracy. For instance, a high-quality magnifying glass helps in detecting even minute imperfections or misalignments that could be missed by the naked eye. Moreover, an advanced digital caliper facilitates exact measurements, ensuring the new pillar perfectly aligns with the vehicle’s structural elements.

In the realm of auto repair shops offering paintless dent repair and automotive body work, these tools become indispensable. They allow technicians to perform meticulous repairs, preserving the integrity and aesthetic appeal of the vehicle. Techniques such as utilizing LED lights for inspection help in identifying hidden defects or disparities in surface finish. This comprehensive approach guarantees that every B-pillar replacement is not just functional but also visually seamless, aligning with industry standards and customer expectations.

Common Issues & How to Avoid Them

When conducting B-pillar replacement, several common issues can arise if proper precautions aren’t taken. One of the most frequent problems is misalignment, which can occur due to imprecise measurements or inadequate mounting techniques. This issue not only compromises the structural integrity of the pillar but also affects the overall aesthetics of the vehicle, leading to an uneven appearance. To avoid misalignment, ensure that all measurements are taken with precision tools and double-check each step during installation.

Another common challenge is poor paint quality following auto painting processes after B-pillar replacement. Inadequate surface preparation or improper painting techniques can result in blotchy finishes, peeling, or uneven coats. To prevent these issues, thoroughly prepare the pillar’s surface by sanding and cleaning to remove any debris or old paint. Use high-quality primers and paints suitable for vehicle restoration, and follow recommended drying times to ensure a durable and smooth finish that enhances the car’s overall restoration.

B-pillar replacement is a critical process that requires meticulous attention to detail. By understanding industry standards, utilizing the right inspection tools, and being proactive in identifying potential issues, you can ensure high-quality replacements that enhance vehicle safety and performance. Remember, thorough quality control and inspection are key to maintaining consistent B-pillar integrity, making every repair count.