B-pillar replacement is a critical automotive repair process ensuring structural integrity and safety after accidents. It involves repairing or replacing the B-pillar connecting the roof to the door frame, restoring vehicle stability and aesthetics. Partial replacements save costs but may compromise integrity, while full replacements offer complete restoration and peace of mind. The automotive industry embraces B-pillar replacement for improved safety and fuel efficiency in modern manufacturing and classic restorations.

In today’s competitive market, understanding B-pillar replacement strategies is crucial for businesses aiming to enhance their operational efficiency. This article delves into the fundamental concept of B-pillar replacement as a foundational solution. We explore the advantages and challenges of both partial and full pillar approaches, offering valuable insights through real-world case studies. By examining successful implementations, readers will gain a comprehensive understanding of how B-pillar replacement can revolutionize their business landscape.

- Understanding B-Pillar Replacement: A Fundamental Concept

- Advantages and Challenges of Partial vs Full Pillar Solution

- Case Studies: Successful Implementations and Their Impacts

Understanding B-Pillar Replacement: A Fundamental Concept

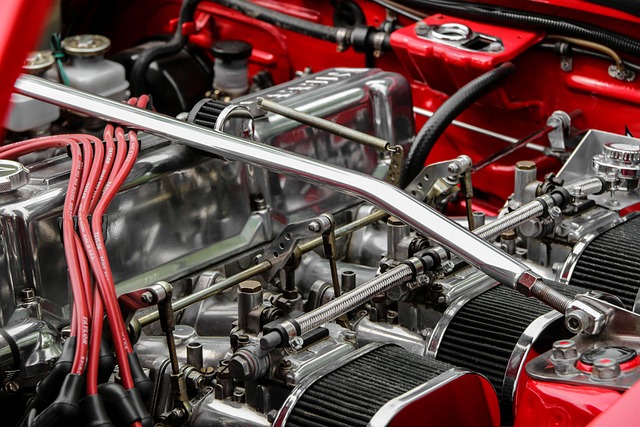

B-pillar replacement is a fundamental concept within automotive body work, addressing structural integrity after a fender bender or similar incident. This process involves the meticulous repair and, in some cases, complete replacement of the B-pillar, a critical component that runs along the side of a vehicle, connecting the roof to the door frame. A skilled technician must ensure the new or repaired B-pillar aligns perfectly with the car’s overall structural design, maintaining safety standards and aesthetics.

Understanding B-pillar replacement is crucial in automotive restoration, as it can significantly impact a vehicle’s stability and resilience against future damage. When performed correctly, this repair allows cars to return to their pre-accident condition, enhancing both performance and peace of mind for the driver. The concept underscores the intricate balance between form and function within modern automobiles.

Advantages and Challenges of Partial vs Full Pillar Solution

Partial or B-pillar replacement offers several advantages in terms of cost and time efficiency for both vehicle owners and repair shops, especially when dealing with minor damage or specific component failure. It involves repairing or replacing only the affected area, minimizing disassembly and assembly processes compared to a full pillar replacement. This can be particularly beneficial for those involved in collision damage repair, as it streamlines the process and reduces overall labor costs.

However, partial solutions also come with challenges. Accurately identifying the extent of damage and selecting the right components is crucial to avoid further complications or structural integrity issues. In some cases, a partial fix may not be aesthetically pleasing, especially if visible parts are affected. For luxury vehicle repair, where precision and aesthetics are paramount, this can pose a significant challenge. Full pillar replacement, while more intensive and costly, ensures a complete restoration, addressing all potential hidden damage and providing a seamless finish, which is essential for maintaining the vehicle’s value and safety in cases of severe collision or structural degradation.

Case Studies: Successful Implementations and Their Impacts

In recent years, the automotive industry has witnessed a significant trend: B-pillar replacement as a game-changer in vehicle design and safety. This innovative approach has sparked numerous case studies showcasing its successful implementations across various sectors, from modern car manufacturing to classic car restoration. For instance, several renowned car repair shops have embraced B-pillar replacement, integrating it into their automotive repair services to enhance structural integrity while reducing weight, leading to improved fuel efficiency.

One notable success story involves a specialist classic car restoration business that utilized B-pillar replacement techniques to revive vintage vehicles. This method allowed them to preserve the original aesthetic appeal while ensuring the safety of drivers and passengers without compromising historical accuracy. Such successful implementations highlight the versatility and benefits of B-pillar replacement, making it a prominent strategy in both contemporary and nostalgic automotive endeavors.

B-pillar replacement strategies offer a compelling balance between cost-efficiency and structural integrity. By understanding the nuances of partial versus full pillar solutions, businesses can make informed decisions based on specific project needs and budget constraints. Case studies highlight successful implementations that have significantly improved structural performance and enhanced safety measures. As the construction industry evolves, adopting innovative B-pillar replacement techniques will continue to shape the future of robust and sustainable building infrastructure.